Resonance testing has emerged as a transformative methodology in quality assurance, offering unprecedented precision in detecting flaws and ensuring product reliability across multiple industries.

🔬 Understanding the Fundamentals of Resonance Testing

Resonance testing represents a sophisticated non-destructive evaluation technique that leverages the natural vibrational frequencies of materials and structures to identify defects, inconsistencies, and potential failure points. Unlike traditional testing methods that may require invasive procedures or extensive disassembly, resonance testing provides comprehensive insights while maintaining the integrity of the tested components.

The principle behind resonance testing is elegantly simple yet profoundly effective. Every object possesses a unique resonant frequency—a natural vibration pattern determined by its physical properties, including mass, stiffness, and geometric configuration. When external energy excites an object at its resonant frequency, the amplitude of vibration increases dramatically, revealing subtle variations that indicate structural anomalies.

Modern quality assurance professionals increasingly recognize that resonance testing delivers a level of sensitivity unattainable through conventional inspection methods. This heightened sensitivity translates directly into improved product quality, reduced failure rates, and substantial cost savings throughout the manufacturing lifecycle.

The Evolution of Quality Assurance Through Resonance Technology

The journey from rudimentary quality control to sophisticated resonance-based testing systems reflects broader technological advancement in industrial manufacturing. Traditional quality assurance relied heavily on visual inspection, dimensional measurements, and destructive sampling—methods that, while valuable, offered limited insight into internal structural integrity.

Resonance testing emerged from research in acoustics and vibration analysis, initially developed for aerospace applications where component failure could have catastrophic consequences. Engineers discovered that analyzing resonant frequencies provided a non-invasive window into material properties and structural soundness.

Today’s resonance testing equipment incorporates advanced sensors, digital signal processing, and artificial intelligence algorithms that can detect frequency variations measured in fractions of a hertz. This technological sophistication enables quality assurance teams to identify defects that would remain invisible to traditional inspection methods.

Key Advantages Over Conventional Testing Methods

Resonance testing offers several compelling advantages that explain its growing adoption across manufacturing sectors:

- Non-destructive evaluation: Components remain intact and fully functional after testing, eliminating waste and allowing 100% inspection rather than statistical sampling

- Rapid assessment: Testing cycles complete in seconds rather than hours, dramatically increasing throughput without compromising quality standards

- High sensitivity: Detection of microcracks, porosity, density variations, and other subtle defects that escape conventional inspection

- Objective measurements: Quantitative data removes subjective judgment from quality decisions, enhancing consistency and traceability

- Cost efficiency: Reduced material waste, lower labor requirements, and prevention of expensive field failures deliver substantial ROI

🎯 Industries Revolutionized by Resonance Testing

The versatility of resonance testing technology has enabled its application across diverse industrial sectors, each benefiting from enhanced quality assurance capabilities tailored to specific requirements.

Aerospace Manufacturing Excellence

Aerospace components operate under extreme conditions where failure is not an option. Resonance testing has become indispensable for verifying turbine blades, structural components, and critical fasteners. The technology detects material inconsistencies, heat treatment variations, and fatigue damage before components enter service, significantly enhancing aviation safety standards.

Leading aerospace manufacturers now integrate resonance testing into production workflows, creating digital resonance signatures for each component. These signatures serve as permanent quality records and enable predictive maintenance strategies that optimize fleet reliability while minimizing operational costs.

Automotive Industry Quality Control

Automotive manufacturers face relentless pressure to improve quality while reducing costs. Resonance testing addresses this challenge by enabling rapid inspection of engine components, suspension parts, and safety-critical elements. The technology identifies casting defects, machining errors, and material variations that could compromise performance or durability.

Several major automotive brands have reported defect detection improvements exceeding 40% after implementing resonance testing systems. These improvements translate directly into reduced warranty claims, enhanced customer satisfaction, and strengthened brand reputation in competitive markets.

Medical Device Precision

Medical devices demand absolute reliability, as failures can directly impact patient safety. Resonance testing provides the precision necessary for validating orthopedic implants, surgical instruments, and diagnostic equipment. The technology verifies material purity, dimensional accuracy, and structural integrity without contaminating sterile components.

Regulatory agencies increasingly recognize resonance testing as a validated quality control method, streamlining approval processes for manufacturers who incorporate this technology into their quality management systems.

Implementing Resonance Testing in Your Quality Framework

Successfully integrating resonance testing requires strategic planning, appropriate equipment selection, and comprehensive staff training. Organizations that approach implementation methodically achieve faster ROI and more sustainable quality improvements.

Assessment and Planning Phase

Begin by conducting a thorough analysis of current quality challenges and testing requirements. Identify components or processes where traditional methods fall short, focusing on areas with high defect rates, customer complaints, or field failures. This assessment establishes clear objectives for resonance testing implementation.

Engage cross-functional teams including quality assurance, engineering, production, and maintenance personnel. Their diverse perspectives ensure the resonance testing solution addresses real operational needs rather than theoretical capabilities.

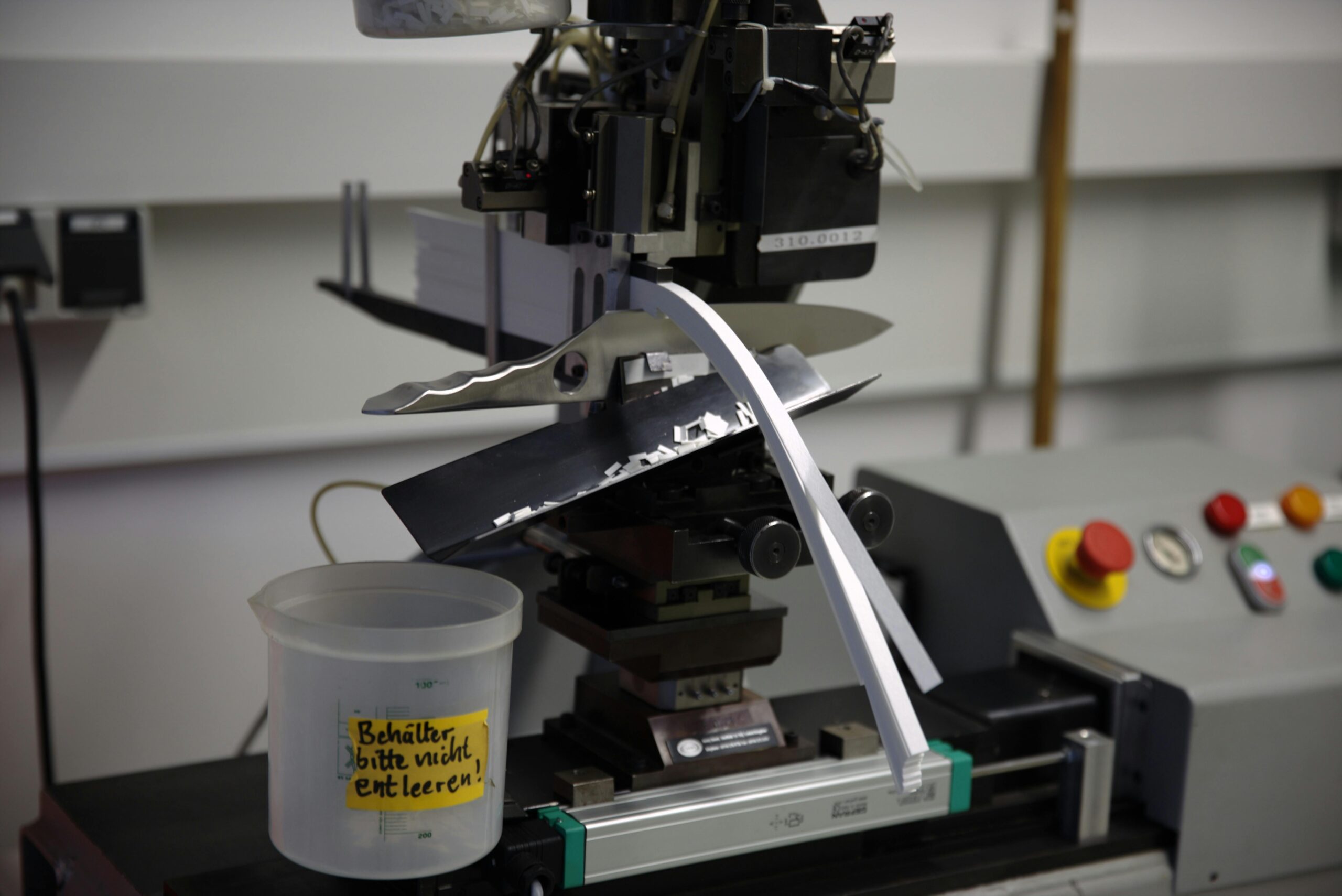

Equipment Selection Criteria

Resonance testing equipment ranges from portable handheld devices to fully automated production line systems. Selection depends on multiple factors:

- Component characteristics: Size, geometry, material composition, and production volume influence equipment requirements

- Inspection environment: Production floor conditions, space constraints, and integration with existing processes

- Defect types: Specific flaws targeted for detection determine sensor sensitivity and frequency range requirements

- Data management: Requirements for documentation, traceability, and integration with quality management systems

- Budget considerations: Initial investment versus long-term operational costs and expected quality improvements

📊 Measuring Success: Key Performance Indicators

Establishing clear metrics enables organizations to quantify the impact of resonance testing on quality assurance performance. These key performance indicators provide objective evidence of value creation and guide continuous improvement efforts.

| KPI Category | Specific Metrics | Target Improvement |

|---|---|---|

| Defect Detection | Detection rate, false positive rate, false negative rate | 30-50% improvement |

| Efficiency | Inspection time per unit, throughput capacity, labor hours | 40-60% reduction |

| Quality Costs | Scrap rate, rework costs, warranty claims, field failures | 25-45% reduction |

| Process Capability | Cpk values, sigma levels, yield rates | 20-35% improvement |

Regular monitoring of these metrics reveals trends, validates improvement initiatives, and identifies opportunities for further optimization. Visualization through dashboards and reports facilitates communication with management and demonstrates the business value of resonance testing investments.

Advanced Applications and Emerging Trends 🚀

The resonance testing field continues evolving rapidly as technological innovations expand capabilities and create new applications previously considered impossible.

Artificial Intelligence Integration

Machine learning algorithms now analyze resonance data patterns with superhuman precision, identifying subtle correlations between frequency signatures and specific defect types. AI-powered systems learn continuously from inspection results, automatically refining detection parameters and reducing false positives.

Predictive analytics leverage historical resonance data to forecast when components will develop defects, enabling proactive intervention before quality issues arise. This shift from reactive to predictive quality assurance represents a fundamental transformation in manufacturing philosophy.

Digital Twin Technology

Forward-thinking manufacturers create digital twins—virtual replicas of physical components that incorporate resonance signatures as fundamental attributes. These digital representations enable simulation of performance under various conditions, optimization of designs for manufacturability, and comprehensive lifecycle tracking.

Digital twins connected to resonance testing systems provide real-time quality feedback, automatically flagging deviations from specifications and triggering corrective actions before defective components progress through production stages.

Portable and Handheld Solutions

Miniaturization and wireless connectivity have produced portable resonance testing devices suitable for field inspections, receiving inspections, and in-process verification. These tools empower technicians to perform sophisticated quality assessments at any location, eliminating bottlenecks caused by transporting components to centralized testing facilities.

Overcoming Implementation Challenges Successfully

While resonance testing delivers substantial benefits, organizations occasionally encounter obstacles during implementation. Understanding common challenges and proven solutions accelerates successful deployment.

Change Management and Cultural Adoption

Introducing new testing methodologies often meets resistance from personnel comfortable with traditional approaches. Success requires comprehensive change management strategies that emphasize benefits, provide adequate training, and celebrate early wins.

Involve quality technicians and inspectors from project inception, soliciting their input on equipment selection and procedure development. This participatory approach builds ownership and transforms potential resisters into enthusiastic advocates.

Technical Calibration and Validation

Resonance testing systems require precise calibration to ensure accurate, repeatable results. Establish rigorous calibration protocols using reference standards traceable to national or international metrology organizations. Document validation studies demonstrating correlation between resonance signatures and actual component quality.

Periodic calibration verification and measurement system analysis maintain confidence in testing accuracy throughout operational life. Automation of calibration procedures reduces human error and ensures consistency across multiple testing stations.

💡 Building a Culture of Continuous Quality Improvement

Resonance testing technology provides tools for quality excellence, but sustained success requires organizational commitment to continuous improvement principles. The most successful implementations occur within cultures that value data-driven decision making, embrace innovation, and prioritize customer satisfaction.

Establish forums where quality data informs product design decisions, manufacturing process improvements, and supplier performance management. Cross-functional review sessions examining resonance testing results often reveal systemic issues requiring coordinated solutions across organizational boundaries.

Recognize and reward employees who leverage resonance testing data to drive improvements. Celebrating successes reinforces the connection between advanced quality assurance methods and business performance, motivating ongoing engagement with quality initiatives.

The Future Landscape of Resonance-Based Quality Assurance

Emerging technologies promise to further enhance resonance testing capabilities over the coming decade. Quantum sensors may achieve sensitivity levels enabling detection of atomic-scale defects. Advanced materials with embedded resonance sensors could provide continuous real-time monitoring throughout product lifecycles.

Integration with blockchain technology may create immutable quality records, enhancing traceability and enabling new business models based on verified quality provenance. As Industry 4.0 principles mature, resonance testing will become increasingly automated and intelligent, requiring minimal human intervention while delivering unprecedented quality assurance.

Organizations investing in resonance testing today position themselves advantageously for this quality-driven future. The competitive advantages gained through superior quality assurance compound over time, creating sustainable differentiation in crowded markets.

Strategic Investment in Quality Excellence ⭐

Resonance testing represents more than technological advancement—it embodies a strategic commitment to quality excellence that resonates throughout entire organizations. Companies embracing this technology demonstrate to customers, employees, and stakeholders that quality remains non-negotiable regardless of competitive pressures or cost constraints.

The initial investment in resonance testing equipment and training delivers returns extending far beyond defect reduction. Enhanced brand reputation, increased customer loyalty, reduced liability exposure, and improved employee morale all contribute to long-term value creation that strengthens organizational resilience.

As manufacturing complexity increases and customer expectations continue rising, resonance testing transitions from competitive advantage to competitive necessity. Organizations delaying adoption risk falling behind competitors who leverage superior quality assurance to capture market share and establish industry leadership.

The power of resonance testing lies not merely in detecting defects but in transforming organizational relationships with quality itself. By providing objective, comprehensive, and rapid quality assessment, resonance technology enables proactive quality management that prevents problems rather than merely identifying them. This fundamental shift elevates quality from inspection function to strategic capability, unlocking potential for excellence that reverberates through every aspect of business performance.

Toni Santos is a vibration researcher and diagnostic engineer specializing in the study of mechanical oscillation systems, structural resonance behavior, and the analytical frameworks embedded in modern fault detection. Through an interdisciplinary and sensor-focused lens, Toni investigates how engineers have encoded knowledge, precision, and diagnostics into the vibrational world — across industries, machines, and predictive systems. His work is grounded in a fascination with vibrations not only as phenomena, but as carriers of hidden meaning. From amplitude mapping techniques to frequency stress analysis and material resonance testing, Toni uncovers the visual and analytical tools through which engineers preserved their relationship with the mechanical unknown. With a background in design semiotics and vibration analysis history, Toni blends visual analysis with archival research to reveal how vibrations were used to shape identity, transmit memory, and encode diagnostic knowledge. As the creative mind behind halvoryx, Toni curates illustrated taxonomies, speculative vibration studies, and symbolic interpretations that revive the deep technical ties between oscillations, fault patterns, and forgotten science. His work is a tribute to: The lost diagnostic wisdom of Amplitude Mapping Practices The precise methods of Frequency Stress Analysis and Testing The structural presence of Material Resonance and Behavior The layered analytical language of Vibration Fault Prediction and Patterns Whether you're a vibration historian, diagnostic researcher, or curious gatherer of forgotten engineering wisdom, Toni invites you to explore the hidden roots of oscillation knowledge — one signal, one frequency, one pattern at a time.