Quality issues can cripple product launches and damage brand reputation. Resonance testing combined with strategic case studies offers a proven methodology to detect defects early, saving time and resources while enhancing product reliability. 🎯

Understanding the Fundamentals of Resonance Testing

Resonance testing represents a sophisticated approach to quality assurance that goes beyond traditional testing methodologies. Unlike conventional testing that examines isolated components, resonance testing evaluates how different system elements interact under various conditions, creating a holistic view of product behavior.

The principle behind resonance testing is simple yet powerful: every system has natural frequencies at which it operates most efficiently—and frequencies at which it fails. By identifying these resonance points early in the development cycle, teams can address vulnerabilities before they become costly problems.

Modern resonance testing incorporates multiple dimensions including mechanical vibrations, electrical frequencies, thermal cycles, and software stress patterns. This comprehensive approach ensures that products can withstand real-world conditions where multiple stressors occur simultaneously rather than in isolation.

Why Traditional Testing Methods Fall Short

Traditional quality assurance processes typically follow linear paths: unit testing, integration testing, system testing, and acceptance testing. While these stages are necessary, they often miss the complex interactions that cause products to fail in customer hands.

The gap between laboratory conditions and real-world usage creates a blind spot. Products may pass all standard tests yet fail when subjected to the unpredictable combinations of stress, temperature, humidity, and usage patterns that customers routinely experience.

Furthermore, traditional testing often occurs late in the development cycle when design changes become prohibitively expensive. This reactive approach means that fundamental flaws may persist through to production, resulting in recalls, warranty claims, and damaged customer relationships.

The Strategic Value of Case Studies in Defect Detection

Case studies transform abstract testing concepts into actionable intelligence. By documenting real-world failures and near-misses, organizations build institutional knowledge that prevents repeated mistakes and accelerates problem-solving capabilities.

Each case study serves as a teaching tool that helps teams recognize patterns in defect formation. When engineers understand how previous products failed under resonance conditions, they can design preventive measures into new products from the conceptual stage.

The documentation of case studies also creates accountability and traceability. Teams can reference specific instances where resonance testing identified critical issues, justifying the investment in comprehensive testing protocols to stakeholders and executives.

Building a Case Study Repository That Drives Results

An effective case study repository requires systematic documentation of every significant finding. Each entry should include the defect description, testing conditions, root cause analysis, resolution strategy, and prevention recommendations for future projects.

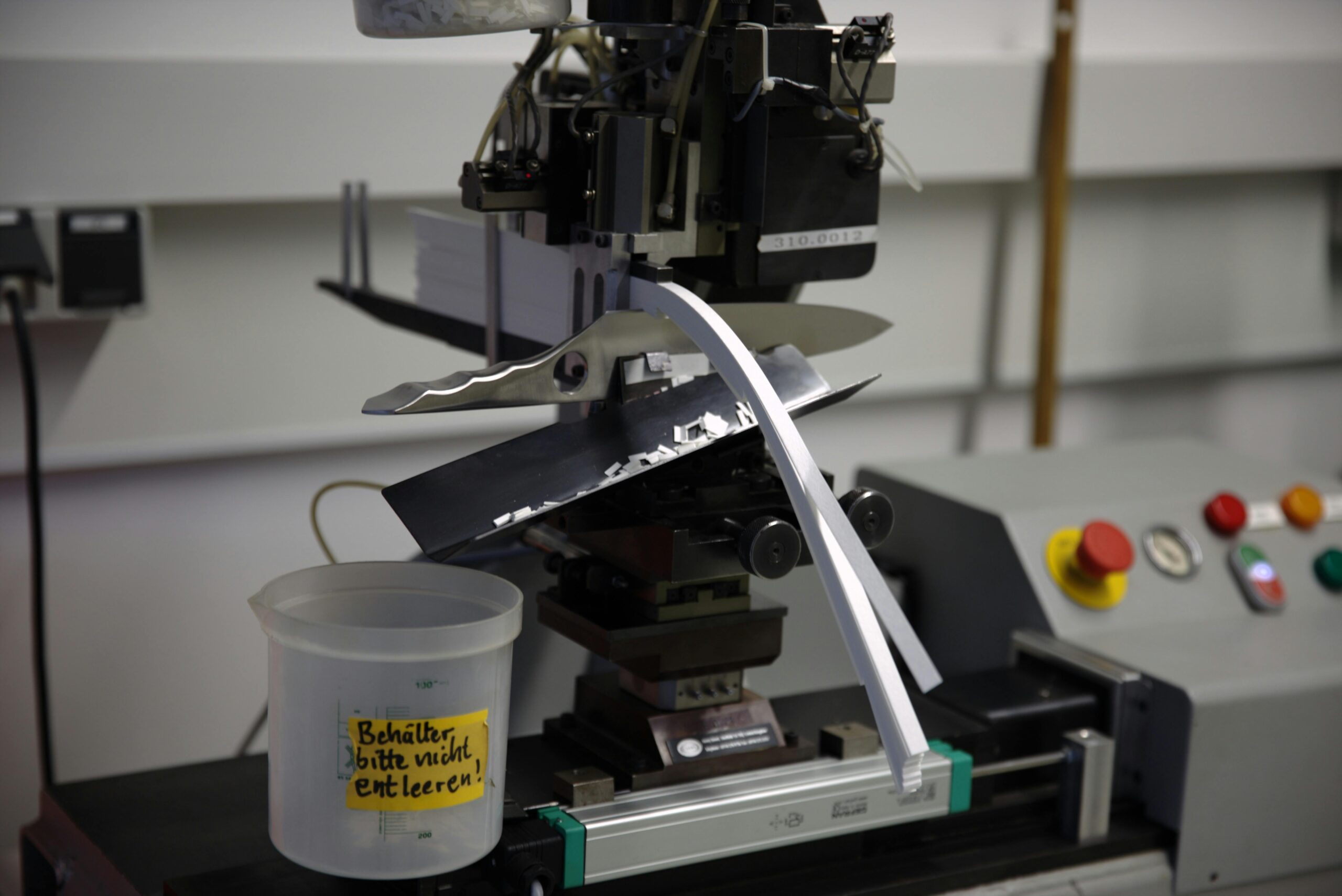

Visual documentation enhances comprehension. High-quality photographs, thermal images, oscilloscope readings, and video recordings of failure modes provide context that text alone cannot convey. These visual elements help engineers quickly grasp complex failure mechanisms.

The repository must be searchable and categorized by product type, defect category, severity level, and detection method. This organization enables rapid retrieval when engineers face similar challenges, dramatically reducing time-to-resolution for new issues.

Implementing Resonance Testing in Your Development Cycle 🔧

Successful implementation begins with executive buy-in and cross-functional collaboration. Quality assurance, engineering, manufacturing, and product management must align on testing objectives and resource allocation.

The integration should start at the design phase rather than after prototypes are built. Early-stage resonance modeling using simulation software can identify potential vulnerabilities before physical testing begins, reducing iteration cycles and material costs.

Testing protocols should mirror actual usage scenarios as closely as possible. This means understanding customer environments, usage patterns, and stress combinations that products will encounter throughout their lifecycle.

Essential Equipment and Tools for Effective Testing

Modern resonance testing requires specialized equipment including vibration tables, environmental chambers, spectrum analyzers, and high-speed data acquisition systems. The investment in quality equipment pays dividends through more accurate and repeatable testing results.

Software tools for data analysis and visualization are equally important. Advanced analytics platforms can identify subtle patterns in massive datasets that human observers might miss, revealing early warning signs of potential failures.

Calibration and maintenance of testing equipment cannot be overlooked. Regular verification ensures that measurements remain accurate and that test results are reliable enough to base critical design decisions upon.

Real-World Success Stories: When Case Studies Save the Day

A leading automotive manufacturer discovered through resonance testing that a dashboard assembly vibrated at the same frequency as the engine at highway speeds. The case study documented how this resonance caused premature failure of electronic displays. By adjusting mounting points and adding damping materials, they prevented a potential recall affecting hundreds of thousands of vehicles.

In the consumer electronics sector, a smartphone manufacturer used case studies from previous product launches to identify thermal resonance issues in a new device. Testing revealed that the processor heat sink resonated with the phone’s structure, creating hotspots that degraded battery performance. The early detection allowed redesign before mass production began.

A medical device company leveraged their case study database to recognize a pattern in ultrasonic sensor failures. Cross-referencing with resonance testing data revealed that certain plastic housings amplified vibrations at specific frequencies, causing premature sensor degradation. Material substitution solved the issue before the product launched.

Quantifying the Financial Impact of Early Detection

The cost of fixing defects increases exponentially as products move through development stages. A defect caught during design might cost hundreds of dollars to address, while the same issue discovered after production launch could cost millions in recalls and lost sales.

Case studies provide concrete data for calculating return on investment for resonance testing programs. By documenting avoided costs, warranty reductions, and improved customer satisfaction scores, quality teams can demonstrate tangible value to financial decision-makers.

Beyond direct cost savings, early defect detection protects brand reputation—an asset difficult to quantify but invaluable in competitive markets. Companies known for reliability command premium pricing and enjoy higher customer loyalty rates.

Developing a Systematic Approach to Case Study Creation

Effective case studies follow a consistent structure that makes information accessible and actionable. Begin with an executive summary that captures the essence of the issue, detection method, and resolution in a few sentences.

The problem statement should detail symptoms, testing conditions, and initial hypotheses. Include relevant technical specifications and environmental factors that contributed to the defect manifestation.

Root cause analysis forms the heart of valuable case studies. Document the investigative process, including dead ends and false leads, to help future teams avoid similar pitfalls. Explain the logic that led to the ultimate cause identification.

Collaborative Review and Continuous Improvement

Case studies should undergo peer review before entering the repository. Cross-functional teams bring diverse perspectives that can identify additional insights or alternative interpretations of the data.

Regular review sessions where teams discuss recent case studies foster collective learning. These sessions create opportunities for junior engineers to learn from experienced colleagues while building organizational knowledge that transcends individual turnover.

The repository itself requires periodic audits to ensure information remains current and relevant. As testing methodologies evolve and new technologies emerge, older case studies may need updates or contextualization to maintain their utility.

Integrating Resonance Testing with Agile Development ⚡

Agile methodologies emphasize rapid iteration and continuous improvement—principles that align perfectly with proactive resonance testing. By incorporating testing into sprint cycles, teams receive immediate feedback that informs design decisions in real-time.

Short testing cycles prevent the accumulation of technical debt. Rather than discovering multiple issues during final testing phases, agile resonance testing identifies problems incrementally, making them easier to address without disrupting project timelines.

Case studies become living documents in agile environments, updated continuously as new information emerges. This dynamic approach ensures that knowledge remains fresh and immediately applicable to current challenges.

Training Teams to Maximize Resonance Testing Value

Technical competence in resonance testing requires both theoretical understanding and practical experience. Training programs should combine classroom instruction on physical principles with hands-on laboratory sessions where engineers conduct actual tests.

Case study analysis should form a core component of training curricula. By working through historical examples, new team members develop the pattern recognition skills necessary to identify emerging issues quickly.

Cross-training between departments enhances testing effectiveness. When design engineers understand testing constraints and quality engineers comprehend design trade-offs, collaborative problem-solving becomes more efficient and innovative.

Creating a Culture of Quality Excellence

Cultural transformation often presents the biggest challenge in implementing comprehensive testing programs. Organizations must shift from viewing quality as a final checkpoint to embracing it as an integral part of every development stage.

Leadership plays a crucial role by celebrating when testing discovers problems rather than punishing teams for defects found. This positive reinforcement encourages thorough testing and honest reporting of issues.

Recognition programs that highlight successful defect detection and resolution motivate teams to maintain high standards. Publishing internal success stories based on case studies reinforces the value of systematic quality practices.

Advanced Techniques for Accelerating Defect Detection 🚀

Machine learning algorithms can analyze historical case study data to predict where future products might be vulnerable. By identifying patterns across multiple projects, these systems flag design elements that warrant additional scrutiny.

Automated testing systems enable continuous resonance monitoring throughout development. Rather than periodic testing sessions, products undergo constant evaluation, generating vast datasets that reveal subtle trends before they become critical issues.

Virtual testing environments using digital twins allow engineers to simulate resonance scenarios without physical prototypes. This capability accelerates the design cycle while reducing material costs and environmental impact.

Measuring Success and Demonstrating Value

Key performance indicators for resonance testing programs should include defect detection rates by development stage, cost avoidance through early identification, and reduction in warranty claims over time.

Time-to-market metrics provide another valuable measure. When resonance testing reduces late-stage design changes, products reach market faster, generating revenue sooner and capturing competitive advantages.

Customer satisfaction scores and product reliability ratings offer external validation of testing effectiveness. Improvements in these metrics demonstrate that internal quality improvements translate to tangible customer benefits.

Future Trends Shaping Quality Assurance Methodologies

The Internet of Things enables products to report their own resonance characteristics from the field. This telemetry data feeds back into case study repositories, creating unprecedented visibility into real-world product behavior.

Artificial intelligence will increasingly automate case study creation, extracting relevant information from test data and generating structured documentation with minimal human intervention. This automation ensures comprehensive coverage without overwhelming engineering resources.

Cloud-based collaboration platforms will connect global teams around shared case study repositories. Engineers in different regions will contribute insights based on local market conditions, creating richer, more diverse quality knowledge bases.

Taking Action: Your Roadmap to Implementation Success

Begin with a pilot program focused on one product line or development team. This limited scope allows for methodology refinement and quick wins that build momentum for broader adoption.

Establish clear documentation standards before launching case study collection. Consistency in format and content ensures that the repository becomes increasingly valuable rather than devolving into an unorganized data dump.

Invest in the infrastructure—both technical and organizational—necessary for long-term success. Quality assurance cannot be an afterthought; it requires dedicated resources, skilled personnel, and executive commitment.

Schedule regular reviews of testing outcomes and case study utilization. These assessments identify opportunities for improvement and demonstrate ongoing value to stakeholders who control resource allocation.

Remember that resonance testing and case study development represent ongoing commitments rather than one-time initiatives. The most successful programs evolve continuously, adapting to new technologies, market demands, and organizational capabilities. By embracing this journey toward quality excellence, organizations position themselves for sustainable competitive advantage built on product reliability and customer trust. The investment in systematic defect detection pays dividends throughout the product lifecycle and across multiple generations of innovation. 🎯

Toni Santos is a vibration researcher and diagnostic engineer specializing in the study of mechanical oscillation systems, structural resonance behavior, and the analytical frameworks embedded in modern fault detection. Through an interdisciplinary and sensor-focused lens, Toni investigates how engineers have encoded knowledge, precision, and diagnostics into the vibrational world — across industries, machines, and predictive systems. His work is grounded in a fascination with vibrations not only as phenomena, but as carriers of hidden meaning. From amplitude mapping techniques to frequency stress analysis and material resonance testing, Toni uncovers the visual and analytical tools through which engineers preserved their relationship with the mechanical unknown. With a background in design semiotics and vibration analysis history, Toni blends visual analysis with archival research to reveal how vibrations were used to shape identity, transmit memory, and encode diagnostic knowledge. As the creative mind behind halvoryx, Toni curates illustrated taxonomies, speculative vibration studies, and symbolic interpretations that revive the deep technical ties between oscillations, fault patterns, and forgotten science. His work is a tribute to: The lost diagnostic wisdom of Amplitude Mapping Practices The precise methods of Frequency Stress Analysis and Testing The structural presence of Material Resonance and Behavior The layered analytical language of Vibration Fault Prediction and Patterns Whether you're a vibration historian, diagnostic researcher, or curious gatherer of forgotten engineering wisdom, Toni invites you to explore the hidden roots of oscillation knowledge — one signal, one frequency, one pattern at a time.